Products and promotions may differ based on your selected region.

Resource Centre

Brochures

General Brochures

X-Ray CT

Laser Radar

Video Measuring Systems

Manual Measuring

Industrial Microscopy

Case Studies

Nikon’s X-ray computed tomography (CT) technology has enabled digital camera lens brand heavyweight Tamron to gain unprecedented insights into the…

View Case StudyNikon’s MCT225 X-ray technologies transform Tochigi Nikon’s plastic moulding

X-ray computed tomography (CT) technology provided by Nikon has enabled optical components production powerhouse Tochigi Nikon to unlock a game-changing…

View Case StudyNikon’s iNEXIV video measuring system gets the stamp of approval from IntriPlex Technologies

Nikon’s iNEXIV VMA-2520 video measuring system – the company’s latest addition to its industry-defining metrology solutions – has empowered IntriPlex,…

View Case StudyKorean steelmaker’s R&D centre invests in X-ray CT for vehicle weld inspection

One of the world’s largest steelmaking companies, POSCO, has invested in an X-ray CT (computed tomography) system for its research…

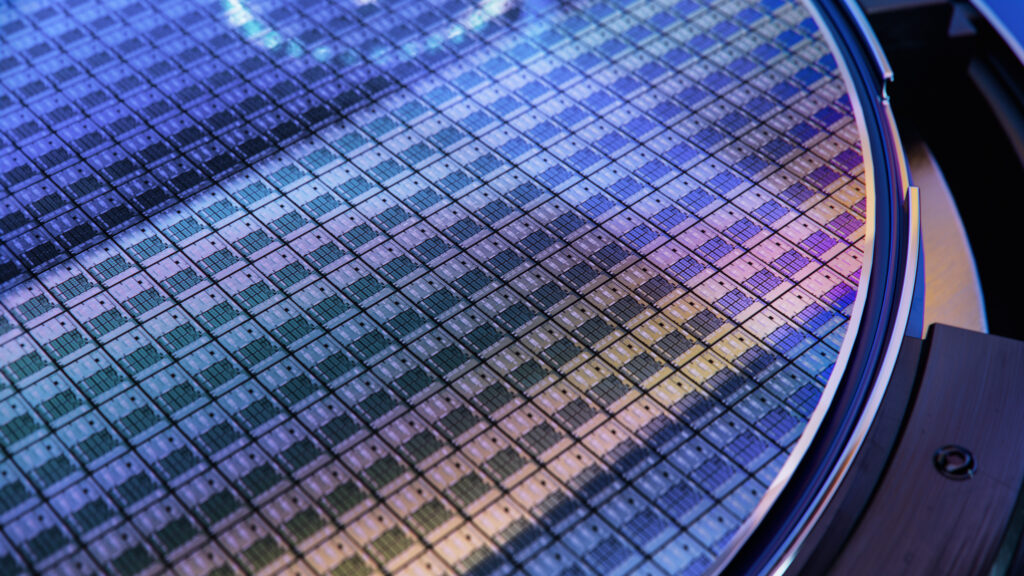

View Case StudyNikon introduces fast, automated system for inspecting wafer ID codes

To assist with quality control in silicon wafer manufacturing companies, the Industrial Metrology Business Unit of Nikon Corporation (https://industry.nikon.com) offers…

View Case StudyRapid, low-cost inspection of semiconductor wafers

The introduction of a programmable video measuring system with automatic handling of semiconductor wafers by the Industrial Metrology Business Unit…

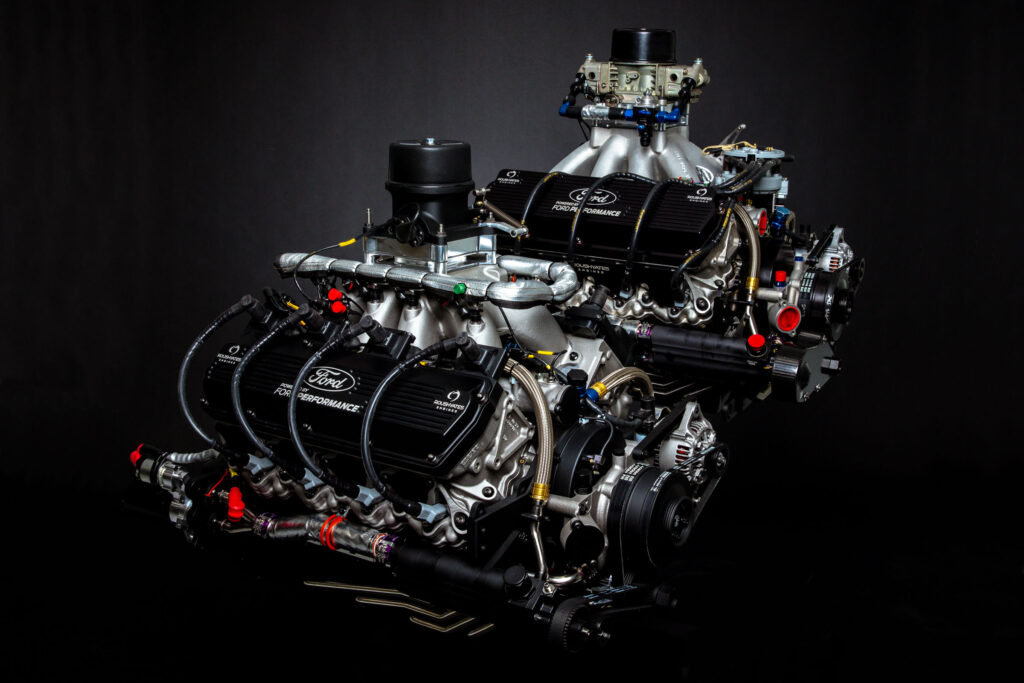

View Case StudyWhether on the track or in the shop, Nikon’s Video Measuring System helps Roush Yates Engines go faster

In North American auto racing circles, any discussion about horsepower must include Roush Yates Engines, which will soon celebrate its…

View Case StudyUniversity extends Finland’s X-ray CT infrastructure

Between 1st May, 2019 and 30th April, 2022, the University of Eastern Finland established Tomolab, a new X-ray CT (computed…

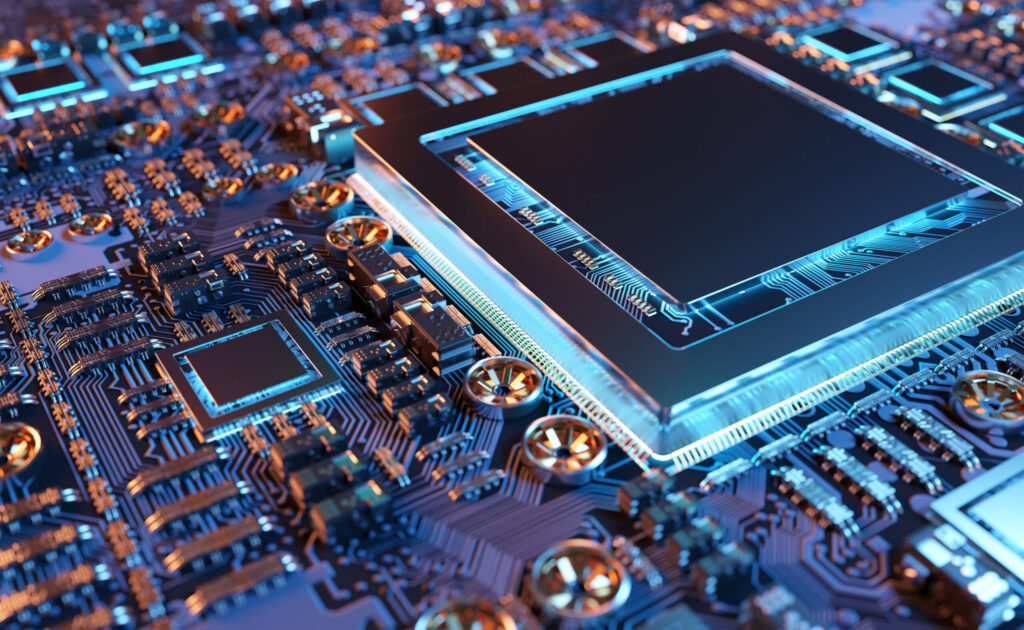

View Case StudyIntegrated circuits inspected faster and more accurately with a Nikon microscope

Headquartered in Cambridge, UK and with a production facility 200 miles north in Sedgefield, PragmatIC Semiconductor (www.pragmaticsemi.com) is a world…

View Case StudyVideo measuring system for real-time QC of lead frames packaging process

Lead frame is the most cost-effective interconnect technology for the fabrication of integrated circuits (ICs) and other electronic devices, and…

View Case StudyWhite Papers

Laser Radar heralds a paradigm shift in automotive metrology

The latest version, APDIS, is a significant step forward in the evolution of the technology and is especially well suited to use in the automotive industry...

View White PaperAPDIS Laser Radar: a paradigm shift away from CMMs for absolute non-contact measurement

APDIS competes even more effectively with the coordinate measuring machine (CMM) in terms of the precision with which components can be inspected...

View White Paper