Products and promotions may differ based on your selected region.

X-Ray and CT Systems

X-ray and CT systems provide insight into the inside of components and specimens, allowing users to visualise, analyse and measure complex internal geometry as well as surfaces, all non-destructively.

Laser Radar Measuring Systems

Laser Radar enables large volume, non-contact measurement in automated or semi-automated installations with unmatched speed and precision.

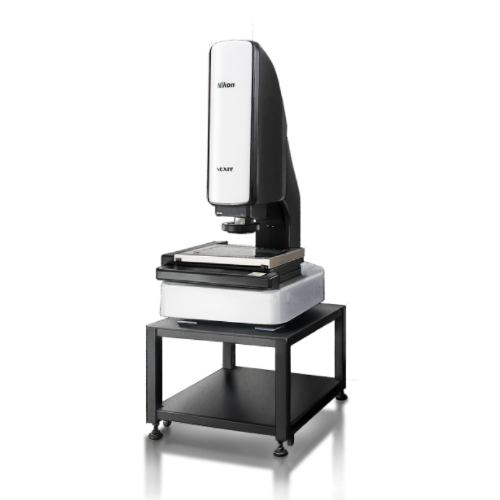

Video Measuring Systems

CNC video measuring enables high accuracy, high speed dimensional measurement across a variety of industrial applications, meeting the demands of rigorous quality control departments.

Optical Manual Measuring

Nikon offers optical manual measuring instruments that deliver high precision and ease of operation across numerous industrial applications.

Industrial Microscopy

The manufacture of optical and digital microscope systems offering outstanding versatility and productivity is another facet of Nikon’s global business.