Products and promotions may differ based on your selected region.

The iNEXIV VMA series provides three types of measurement envelope together with wide field of view optics. These touch probe-ready systems are ideal for a wide variety of industrial measurement, inspection and quality control applications using both vision and tactile measurement.

The VMA series is optimised for speed and ease-of-use as well as repeatable, accurate measurement of a variety of different components.

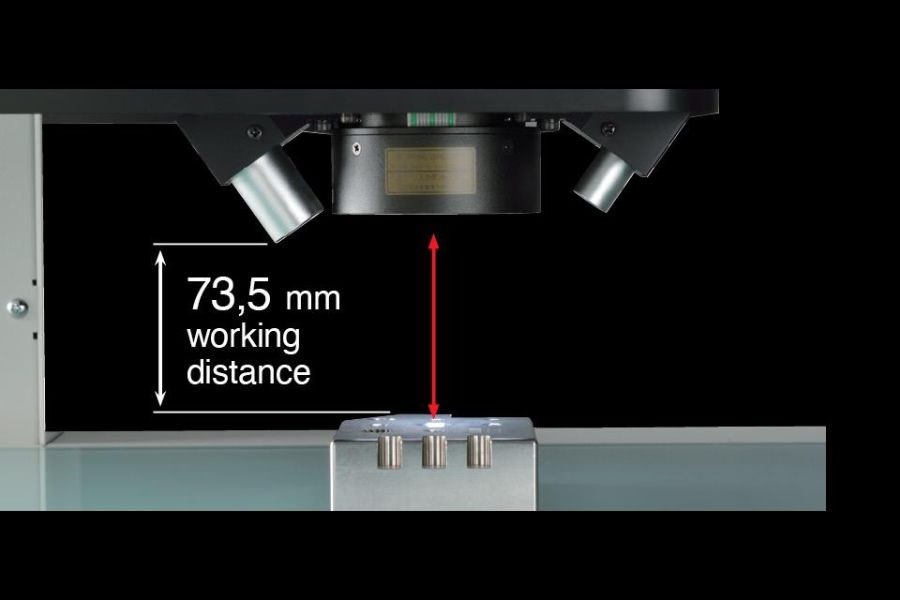

The iNEXIV VMA has a long working distance of 73.5mm. It is well suited to depth measurements where the height variation is large, such as on high bosses and in fine, deep holes.

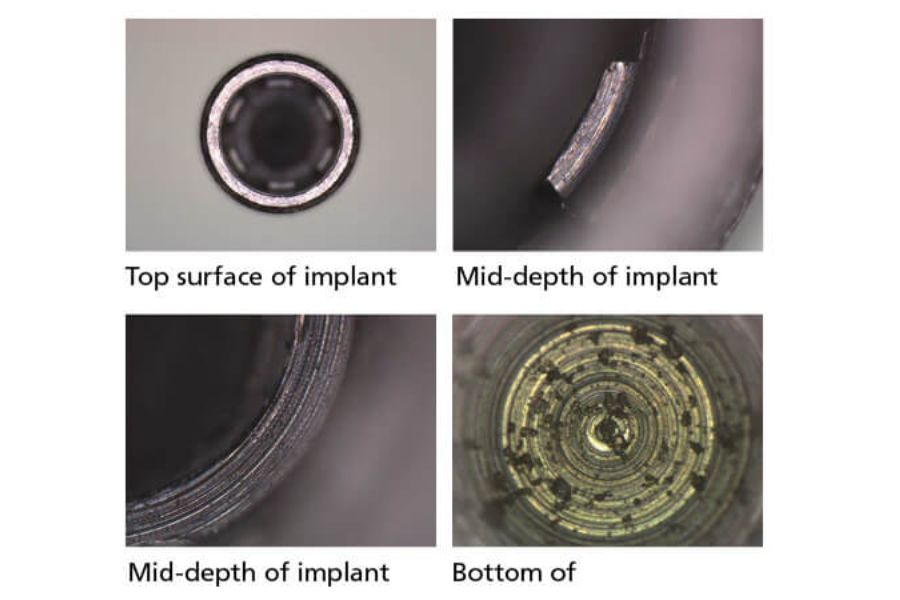

The iNEXIV VMA is able to measure the dimensions and angles of non-visible features, such as holes on the side of a component.

| VMA-2520 | VMA-4540 | VMA-6555 | |

| Stroke (X x Y x Z) | 250 x 200 x 200 mm | 450 x 400 x 200 mm | 650 x 550 x 200 mm |

| Measurement Range with TP (Touch Probe) | 200 x 200 x 166 mm (TP20) 200 x 200 x 170 mm (TP200) 250 x 200 x 200 mm (with Vision AF) | 400 x 400 x 166 mm (TP20) 400 x 400 x 170 mm (TP200) 450 x 400 x 200 mm (with Vision AF) | 600 x 550 x 166 mm (TP20) 600 x 550 x 170 mm (TP200) 650 x 550 x 200 mm (with Vision AF) |

| Measurement Range with TP & MCR20 *1 | 175 x 200 x 166 mm (TP20) 175 x 200 x 170 mm (TP200) 225 x 200 x 200 mm (with Vision AF) | 325 x 400 x 166 mm (TP20) 325 x 400 x 170 mm (TP200) 375 x 400 x 200 mm (with Vision AF) | 525 x 550 x 166 mm (TP20) 525 x 550 x 170 mm (TP200) 575 x 550 x 200 mm (with Vision AF) |

| Minimum Readout | 0.1 µm | ||

| Maximum Sample Weight (Accuracy Guaranteed) | 15 kg (5 kg) | 40 kg (20 kg) | 50 kg (30 kg) |

| Maximum Permissable Error *2 (L = Length in mm) | EUX,MPE EUY,MPE: 2+8L/1000 µm EUXY,MPE: 3+8L/1000μm EUZ,MPE: 3+L/50μm *3 | EUX,MPE EUY,MPE: 2+6L/1000 µm EUXY,MPE: 3+6L/1000μm EUZ,MPE: 3+L/100μm *3 |

|

| Camera | Black & White 1/3" CCD, Color 1/3" (option) | ||

| Working Distance | 73.5 mm (63 mm with Laser AF) | ||

| Magnification | Optical: 0.35 to 3.5x (0.52x to 5.2x high magnification is available as an option) On screen: 12.6 to 126x with 24-inch WUXGA (1920 x 1200 pixels) monitor |

||

| FOV size on stage | 13.3 x 10 mm to 1.33 x 1 mm (8.9 x 6.7 mm to 0.89 x 0.67 mm with high-magnification option) | ||

| Auto Focus | Vision AF, Laser AF (option) | ||

| Illumination | Contour Illumination and Surface Illumination: White LED diascopic illumination Oblique Illumination: 8-segment white LED ring |

||

| Video Resolution | 640 x 480 pixels | ||

| Touch Probe (optional) | Renishaw® TP200/TP20 | ||

| Power Source | 100 V - 240 V, 50/60 Hz | ||

| Power Consumption | 5 A (100V) -2.5 A (240 V) (excluding power consumption of host computer and its peripherals) | 5 A (100V) -2.5 A (240 V) | |

| Main body (W x D x H) | 650 x 700 x 1557 mm 110 kg | 1000 x 1340 x 1553 mm 500 kg | 1200 x 1640 x 1553 mm 665 kg |

| Controller | 145 x 400 x 390 mm 14 kg | 145 x 400 x 390 mm 14 kg | 145 x 400 x 390 mm 14 kg |

| Operational environment | Temperature: 10 to 35ºC Humidity: 70% or less |

||

| Accuracy guaranteed temperature | 20°C ±0.5K | ||

*1: The iNEXIV-dedicated MCR20 can be used for both TP20 and TP200

*2: Nikon’s in-house test at 20°C ±0.5k

*3: With TP or Laser AF

If you would like further details on this product or a more in-depth description, our expert team will provide you with additional information and, if required, arrange an on-site visit.

Talk to us in detail about your project and our experts will advise you on the best inspection system to meet your requirements.

Please fill out the form opposite and we will get in touch with you shortly.